Standard Certified By

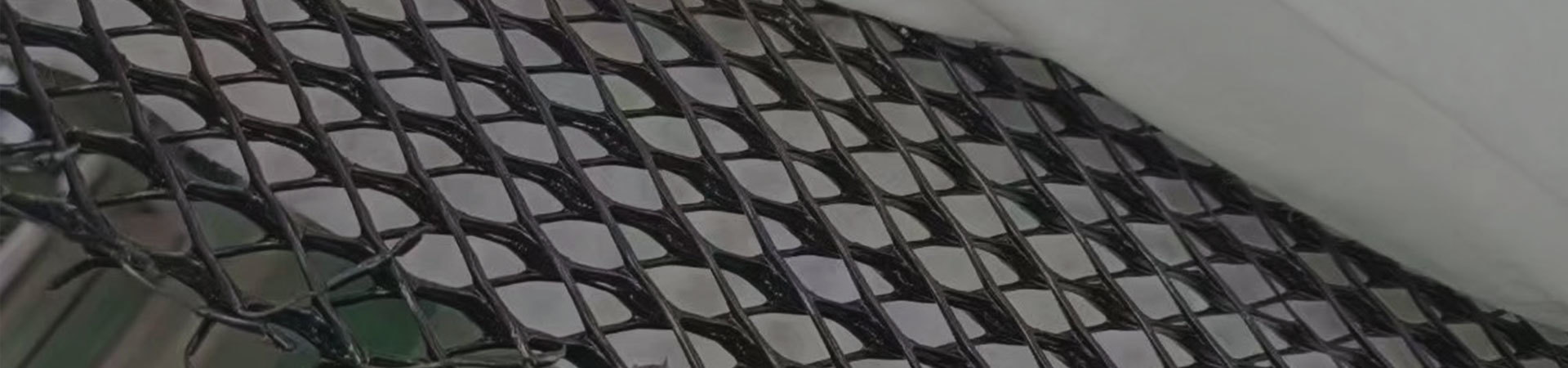

HDPE 3D Composite Drainage Net

Classification :

PRODUCT DETAILS

What is HDPE 3D Composite Drainage Geonet?

HX® geocomposite drainage net is made from lightweight high-density polyethylene (HDPE) and designed with a thin two-dimensional composite construction. The drainage net is bonded to a non-woven geotextile which provides optimum combination of high through-flow capacity for rapid drainage whilst simultaneously preventing fine soil particles from migrating into the drainage core.

The three-dimensional composite drainage network is made of unique three-dimensional geonet bonded geotextile on both sides. The combination of geotextile (filter function) and geonet (drainage and protection function) provides complete "filter drainage protection" effect.

What are the applications of HDPE 3D Composite Drainage Geonet?

HX® 3D composite drainage network is a drainage system with excellent performance, widely used in urban roads, car parks, parks, squares and other places.

Anti seepage and anti-corrosion: Composite drainage networks can prevent the loss of soil particles, protect soil stability, and prevent fine particles from infiltrating the drainage system, avoiding clogging of drainage holes.

Strengthening soil: Composite drainage networks can closely integrate with soil, enhance the tensile and shear strength of soil, improve the stability and bearing capacity of soil, and be used for slope and slope reinforcement to slow down soil erosion and landslide occurrence.

Plant growth: Composite drainage networks can serve as the bottom layer of vegetation coverage systems, providing good drainage and ventilation conditions, promoting plant growth and root development, and are used for greening, landscape, and ecological engineering.

· Retaining walls drainage, underground structure drainage, garden and playground drainage.

· Drainage of highway subgrade and pavement, railway subgrade drainage, tunnel drainage.

· Landfill leachate collection in landfill liners, leak detection, caps and closures.

· Methane gas collection, pond leak detection, erosion control.

Performance

HX® geocomposite drainage net are an economical alternative to traditional granular drainage layers because they better optimize landfill space and speed up the installation of lightweight composite materials.

Durable and compression resistant: Able to withstand high loads of more than 450 kPa.

Fast drainage: High flow capacity for rapid drainage while preventing fine soil particles from migrating into the drainage core.

Protect the structure: from damage caused by backfill materials.

Simple installation: Can be easily unfolded, allowing large surface areas to be created quickly and efficiently.

Reduce losses: Due to the light weight of the drainage net, damage to adjacent structures or materials (such as plastic liners) can be minimized, thereby reducing safety risks on the construction site.

HX® geocomposite drainage net have a good track record in landfill and mining projects in Australia and New Zealand. HX® geocomposite drainage net offers single-sided or double-sided geotextiles, with lighter or heavier grades depending on the specialty application.

|

Property |

Test Method |

Test Value Based on Geonet Thickness |

Test Frequency |

|||||

|

(a) Geonet (before lamination) |

|

5.0mm |

6.3 mm |

7.6mm |

|

|||

|

Thickness(1), mm (min. ave.) |

D5199 |

5.1 |

6.3 |

7.6 |

per 22,000kg |

|||

|

Density(2), g/cc (min. ave.) |

D1505/D792 |

0.95 |

0.95 |

0.95 |

per 22,000kg |

|||

|

Carbon Black Content,% |

D1603/D4218 |

1.5 to 3.0 |

1.5 to 3.0 |

1.5 to 3.0 |

per 45,000kg |

|||

|

Tensile Strength(3), kN/m (min. ave.) |

D7179 |

7.9 |

10.5 |

13.1 |

per 22,000kg |

|||

|

Compressive Strength(4), kPa(min. ave.) |

D6364 |

830 |

830 |

830 |

per 45,000kg |

|||

|

Flow Rate/Width(5), (l/min.)/m (min. ave.) |

D4716 |

87 |

124 |

161 |

per 90,000kg |

|||

|

(b) Geotextile (before lamination)(7) |

|

|

|

|

|

|||

|

Mass/Unit Area, g/m2(MARV) |

D5261 |

200 |

270 |

200 |

270 |

200 |

270 |

Note (8) |

|

Grab Strength,N(MARV) |

D4632 |

700 |

890 |

700 |

890 |

700 |

890 |

|

|

Grab Elongation,%(MARV) |

D4632 |

50 |

50 |

50 |

50 |

50 |

50 |

|

|

Tear Strength,N(MARV) |

D4533 |

250 |

350 |

250 |

350 |

250 |

350 |

|

|

Puncture Strength,kN(MARV) |

D6241 |

1.37 |

1.92 |

1.37 |

1.92 |

1.37 |

1.92 |

|

|

Permittivity, sec'(MARV) |

D4491 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

|

|

AOS, mm (MaxARV) |

D4751 |

0.25 |

0.25 |

0.25 |

0.25 |

0.25 |

0.25 |

|

|

UV Stability, % ret. (500 hr.) |

D7238 |

50 |

50 |

50 |

50 |

50 |

50 |

|

|

(c) Single-Sided Laminated Composite |

|

|

|

|

|

|

|

|

|

Flow Rate/Width(6),(l/min.)/m (min. ave.) |

D4716 |

19 |

19 |

31 |

31 |

44 |

44 |

per 90,000kg |

|

Ply Adhesion(9, N/m (min. ave.) |

D7005 |

170 |

170 |

170 |

170 |

170 |

170 |

per 45,000kg |

|

(d) Double-Sided Laminated Composite |

|

|

|

|

|

|

|

|

|

Flow Rate/Width(6),(l/min.)/m (min.-ave.) |

D4716 |

6 |

6 |

19 |

19 |

37 |

37 |

per 90,000kg |

|

Ply Adhesion(9), N/m (min. ave.) |

D7005 |

170 |

170 |

170 |

170 |

170 |

170 |

per 45,000kg |

|

(1)The diameter of the presser foot shall be 56 mm and the pressure shall be 2 kPa.per ASTM D5199 Procedure"A" |

||||||||

PROJECT CASES

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

LISTEN & DELIVER TRUSTED SOIUTIONS.

DOWNLOADS