Standard Certified By

Waterproof Geomembrane

Classification :

PRODUCT DETAILS

What is Textured geomembrane?

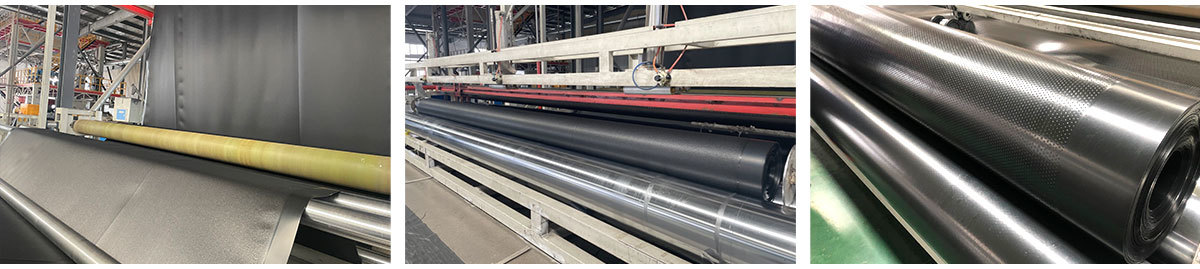

HX® Textured geomembrane is a type of geomembrane that has a rough or textured surface. This texture helps to prevent the geomembrane from slipping or sliding, and it also helps to increase the friction between the geomembrane and the underlying surface. This makes textured geomembrane a good choice for applications where there is a risk of slippage, such as landfill liners and dams.

Textured geomembrane is made from the same materials as smooth geomembrane. However, the textured surface is created by a process called embossing. Embossing is a process that uses a mold to create a raised pattern on the surface of the geomembrane.

The texture of textured geomembrane can vary depending on the type of mold that is used. Some textured geomembranes have a smooth, pebbled texture, while others have a more pronounced, ridged texture. The type of texture that is best for a particular application will depend on the specific requirements of the project.

Specification:

Black, white, green, blue etc. or according to your.

Width: 1-8m

Length: 50-150m as customized

Thickness:0.2mm-3.0mm

Color: Black, white,blue customized products can be supported according to customer needs

Types:Single-sided textured geomembrane,double-sided textured geomembrane,pillar point geomembrane

What is the types of Textured geomembrane?

There are three main types of textured geomembrane:

Single-textured geomembrane: This type of geomembrane has a single type of texture on the entire surface. The texture can be smooth, pebbled, or ridged, depending on the specific application.

Applications: Landfill liners, dams, erosion control.

Double-textured geomembrane: This type of geomembrane has two different types of textures on the surface. The two textures are typically arranged in a checkerboard pattern. This type of geomembrane is often used in applications where there is a need for both increased friction and reduced adhesion.

Applications: Traffic barriers, aquaculture ponds

Pillar point geomembrane: Generally not selected.

Here is a table that summarizes the key differences between single-textured and double-textured geomembrane:

The type of textured geomembrane that is best for a particular application will depend on the specific requirements of the project. For example, single-textured geomembrane is often used in landfill liners and dams because it provides increased friction and reduced adhesion. Double-textured geomembrane is often used in traffic barriers and aquaculture ponds because it provides both increased friction and reduced adhesion.

Here are some additional factors to consider when choosing a textured geomembrane:

Thickness: The thickness of the geomembrane will affect its strength and durability. Thicker geomembranes are more resistant to punctures and tears, but they are also more expensive.

Material: The material that the geomembrane is made from will affect its properties. HDPE geomembranes are more resistant to chemicals and UV radiation than PVC geomembranes.

Price: Textured geomembrane is more expensive than smooth geomembrane. However, the additional cost is often justified by the improved performance of textured geomembrane.

By carefully considering all of these factors, you can choose the right textured geomembrane for your project.

What are the applications of Textured geomembrane?

- Landfill liners: Textured geomembrane is often used as a liner for landfills. The textured surface helps to prevent the landfill from leaking and also helps to reduce the adhesion of materials, such as dirt and debris.

- Dams and levees: Textured geomembrane is also used in dams and levees. The textured surface helps to increase the friction between the geomembrane and the underlying surface, which helps to prevent the dam or levee from slipping or sliding.

- Erosion control: Textured geomembrane can be used to control erosion. The textured surface helps to prevent soil from eroding and also helps to reduce the adhesion of materials, such as dirt and debris.

- Rooftop membranes: Textured geomembrane can be used as a roofing membrane. The textured surface helps to prevent water from pooling on the roof and also helps to reduce the adhesion of materials, such as dirt and debris.

- Aquaculture ponds: Textured geomembrane can be used in aquaculture ponds. The textured surface helps to prevent fish from escaping and also helps to reduce the adhesion of materials, such as algae and sediment.

- Traffic barriers: Textured geomembrane can be used as a traffic barrier. The textured surface helps to prevent vehicles from slipping or sliding and also helps to reduce the adhesion of materials, such as dirt and debris.

These are just some of the most common applications for textured geomembrane. Textured geomembrane is a versatile product that can be used in a variety of other applications as well.

Here are some additional benefits of using textured geomembrane:

Here are some additional benefits of using textured geomembrane:

- Increased friction: HX® textured surface of textured geomembrane helps to increase the friction between the geomembrane and the underlying surface. This makes it less likely that the geomembrane will slip or slide, which is important in applications where there is a risk of erosion or flooding.

- Reduced adhesion: HX® textured surface of textured geomembrane also helps to reduce the adhesion of materials, such as dirt and debris. This makes it easier to clean and maintain the geomembrane, and it also helps to extend the lifespan of the geomembrane.

- Improved drainage: HX® textured surface of textured geomembrane can help to improve drainage. This is important in applications where water runoff is a concern, such as landfill liners and dams.

- Enhanced durability: HX® textured surface of textured geomembrane can help to enhance the durability of the geomembrane. This is important in applications where the geomembrane will be exposed to harsh environments, such as UV radiation and chemicals.

If you are looking for a geomembrane that is resistant to slipping, sliding, and adhesion, then textured geomembrane is a great option. It is a versatile and durable product that can be used in a variety of applications.

|

Properties |

Test Method |

Test Value |

Testing Frequency |

|||||||||||||

|

0.75 |

1.00 |

1.25 |

1.50 |

2.00 |

2.50 |

3.00 |

|

|||||||||

|

Thickness (min. ave.) - mm |

D 5994 |

nom.-5% |

nom.-5% |

nom.-5% |

nom.-5% |

nom.-5% |

nom.-5% |

nom.-5% |

per roll |

|||||||

|

Asperity Height mils (min. ave.) - mm |

D 7466 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

every 2nd roll (1) |

|||||||

|

Formulated Density (min. ave.) - g/cc |

D 1505/D 792 |

0.95-0.97 |

0.95-0.97 |

0.95-0.97 |

0.95-0.97 |

0.95-0.97 |

0.95-0.97 |

0.95-0.97 |

90,000 kg |

|||||||

|

Tensile Properties (min. ave.) (2) |

D 6693 |

11 |

15 |

18 |

22 |

29 |

37 |

44 |

22 |

|||||||

|

Tear Resistance (min. ave ) - N |

D 1004 |

93 |

125 |

156 |

187 |

249 |

311 |

374 |

20,000 kg |

|||||||

|

Puncture Resistance (min. ave.) - N |

D 4833 |

200 |

267 |

333 |

400 |

534 |

667 |

800 |

20,000 kg |

|||||||

|

Stress Crack Resistance - hr. (3) |

D 5397 |

500 |

500 |

500 |

500 |

500 |

500 |

500 |

per GRI GM10 |

|||||||

|

Carbon Black Content (range) - % |

D 4218 (4) |

2.0-3.0 |

2.0-3.0 |

2.0-3.0 |

2.0-3.0 |

2.0-3.0 |

2.0-3.0 |

2.0-3.0 |

9,000 kg |

|||||||

|

Carbon Black Dispersion |

D 5596 |

note (5) |

20,000 kg |

|||||||||||||

|

Oxidative Induction Time (OIT) (min. ave.) (6) |

D 8117 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

90,000 kg |

|||||||

|

Oven Aging at 85°C (6) (7) |

D 5721 |

|

|

|

|

|

|

|

per each formulation |

|||||||

|

UV Resistance (8) |

D 7238 |

N.R.(9) |

per each formulation |

|||||||||||||

|

50 |

50 |

50 |

50 |

50 |

50 |

50 |

||||||||||

(1) Alternate the measurement side for double sided textured sheet

(2) Machine direction (MD) and cross machine direction (XMD) average values should be on the basis of 5 test specimens each direction. Yield elongation is calculated using a gage length of 33 mm . Break elongation is calculated using a gage length of 50 mm

(3) The SP-NCTL test is not appropriate for testing geomembranes with textured or irregular rough surfaces. Test should be conducted on smooth edges of textured rolls or on smooth sheets made from the same formulation as being used for the textured sheet materials.The yield stress used to calculate the applied load for the SP-NCTL test should be the manufacturer’s mean value via MQC testing.

(4) Other methods such as D 1603 (tube furnace) or D 6370 (TGA) are acceptable if an appropriate correlation to D 4218 (muffle furnace) can be established.

(5) Carbon black dispersion (only near spherical agglomerates) for 10 different views: 9 in Categories 1 or 2 and 1 in Category 3.

(6) The manufacturer has the option to select either one of the OIT methods listed to evaluate the antioxidant content in the geomembrane.

(7) It is also recommended to evaluate samples at 30 and 60 days to compare with the 90 day response.

(8) The condition of the test should be 20 hr. UV cycle at 75oC followed by 4 hr. condensation at 60oC.

(9) Not recommended since the high temperature of the Std-OIT test produces an unrealistic result for some of the antioxidants in the UV exposed samples.

(10) UV resistance is based on percent retained value regardless of the original HP-OIT value.

PROJECT CASES

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

LISTEN & DELIVER TRUSTED SOIUTIONS.

DOWNLOADS