Standard Certified By

PP Short Fiber Nonwoven Geotextile

Classification :

PRODUCT DETAILS

What is the PP Short Fiber Nonwoven Geotextile ?

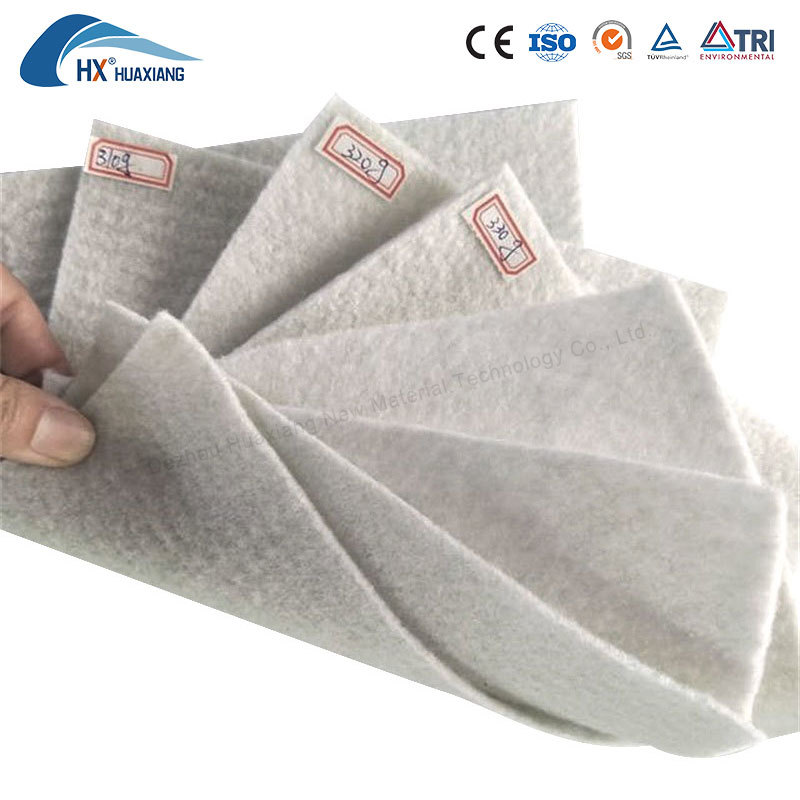

HX® Polypropylene short fiber nonwoven geotextile is made of polypropylene as raw materials and is processed by combing network paving equipment and acupuncture equipment.

Polypropylene short fiber nonwoven geotextile is also known as "PP short fiber nonwoven geotextile". Polypropylene short fiber nonwoven geotextile has good breathability and water permeability, which can form drainage channels inside the soil, allowing water flow to pass through and effectively controlling the loss of sand and gravel. It is widely used in filtration, separation, protection, and drainage of civil environmental engineering and construction engineering.

What are the types of Nonwoven Geotextile?

Short Fiber Non-Woven Geotextiles: These are manufactured by mechanically orienting and interlocking polypropylene fibers to form a sturdy and dimensionally stable network. These geotextiles are commonly used in applications that require superior filtration and secure soil separation.

Continuous Filament Non-Woven Geotextiles: These are composed of polyester yarns formed into a complex 3D network and then consolidated by needle punching. They are commonly used in road construction, filtration, and drainage systems due to their high permeability and toughness.

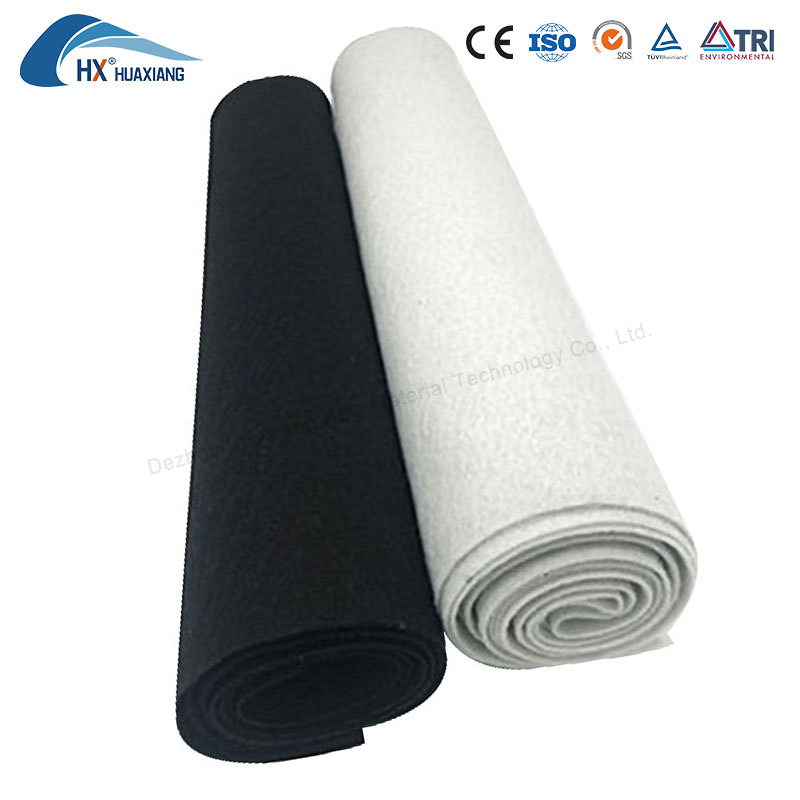

Width: 1-6m

Weight:100-1200g/m2

Length: 50-300m as customized

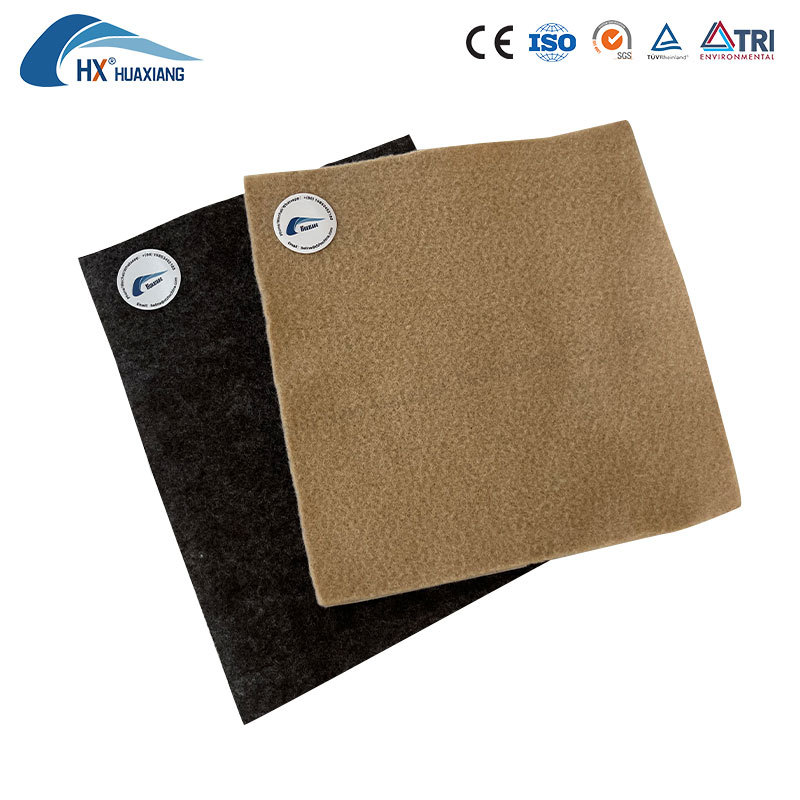

Colours:Black, white, green, etc. or according to your requirements.

Each type of non-woven geotextile has its specific characteristics and applications, so it is crucial to select the right type based on the requirements of the project.

|

|

|

|

Where is nonwoven geotextile fabric used?

Geotextile fabric is widely used in civil engineering and construction projects. Some of the common uses include:

Road Construction: Geotextile fabric helps to stabilize the ground and increase the lifespan of the road by preventing the mixing of sub-base and subgrade layers.

Erosion Control: It can be used to protect soil from erosion, especially on slopes and in areas exposed to water flow.

Drainage: Geotextiles have excellent water permeability and are used in drainage systems to filter out soil particles while allowing water to pass.

Landfill: In landfill sites, geotextile fabric is used to separate different layers and prevent contamination of groundwater.

|

|

|

|

Performance

HX® Short fiber non woven geotextile fabric is a versatile and effective material that can be used in a wide variety of applications.

Tensile strength: HX® Short fiber non woven geotextile fabric has a tensile strength of 100 to 200 kN/m. This means that it can withstand a force of up to 100 to 200 kilonewtons per meter before it breaks.

Water permeability: HX® Short fiber non woven geotextile fabric has a water permeability of 100 to 200 cm/min. This means that it can allow water to flow through it at a rate of 100 to 200 centimeters per minute.

Filtration rating: HX® Short fiber non woven geotextile fabric has a filtration rating of 200 to 300 microns. This means that it can filter out particles that are larger than 200 to 300 microns in diameter.

Chemical resistance: HX® Short fiber non woven geotextile fabric is resistant to a variety of chemicals, including acids, alkalis, and solvents.

UV resistance: HX® Short fiber non woven geotextile fabric is resistant to UV radiation. This means that it can withstand exposure to sunlight without degrading.

In addition to these physical properties, HX® Short fiber non woven geotextile fabric also has a number of other advantages, including:

Lightweight: HX® Short fiber non woven geotextile fabric is lightweight, making it easy to transport and install.

Durable: HX® Short fiber non woven geotextile fabric is durable and can withstand a variety of conditions.

Cost-effective: HX® Short fiber non woven geotextile fabric is cost-effective, making it a good option for a variety of applications.

It is lightweight, durable, cost-effective, and has excellent physical properties. If you are looking for a geotextile fabric that can meet your needs, HX® Short fiber non woven geotextile fabric is a great option.

|

|

|

|

| Properties | Test Method | Unit | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 |

| unit weight variation | % | ±6 | ||||||||||

| grab strength | MD | N | ≥350 | ≥800 | ≥1100 | ≥1500 | ≥2000 | ≥2400 | ≥2800 | ≥3200 | ≥3600 | ≥4000 |

| TD | ≥350 | ≥800 | ≥1100 | ≥1500 | ≥2000 | ≥2400 | ≥2800 | ≥3200 | ≥3600 | ≥4000 | ||

| grab elongation | MD | % | 60~80 | 60~80 | 60~85 | 50~100 | 50~100 | 50~100 | 50~100 | 50~100 | 50~100 | 50~100 |

| TD | 50~70 | 50~70 | 50~75 | 50~100 | 50~100 | 50~100 | 50~100 | 50~100 | 50~100 | 50~100 | ||

| grab elongation at 50N | MD | % | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 |

| TD | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | ||

| Trapezoidal tear strength | MD | N | ≥100 | ≥350 | ≥420 | ≥500 | ≥580 | ≥660 | ≥750 | ≥840 | ≥920 | ≥1000 |

| TD | ≥100 | ≥350 | ≥420 | ≥500 | ≥580 | ≥660 | ≥750 | ≥840 | ≥920 | ≥1000 | ||

| CBR mullen brust strength | KN | ≥1.3 | ≥2.0 | ≥3.5 | ≥4.3 | ≥5.5 | ≥6.5 | ≥7.5 | ≥8.5 | ≥9.5 | ≥10.5 | |

| breaking strength | MD | KN | ≥5.0 | ≥11 | ≥16 | ≥22 | ≥28 | ≥35 | ≥43 | ≥50 | ≥56 | ≥65 |

| TD | ≥5.0 | ≥11 | ≥16 | ≥22 | ≥28 | ≥35 | ≥43 | ≥50 | ≥56 | ≥65 | ||

| 45°oblique | ≥5.0 | ≥11 | ≥16 | ≥22 | ≥28 | ≥35 | ≥43 | ≥50 | ≥56 | ≥65 | ||

| breaking elongation | MD | % | 40~75 | 40~75 | 40~80 | 50~90 | 50~90 | 50~90 | 50~90 | 50~90 | 50~90 | 50~90 |

| TD | 45~65 | 45~65 | 45~70 | 50~90 | 50~90 | 50~90 | 50~90 | 50~90 | 50~90 | 50~90 | ||

| breaking elongation at 50N | MD | % | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 |

| TD | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | 3~6 | ||

| puncture resistance | N | ≥200 | ≥430 | ≥650 | ≥900 | ≥1200 | ≥1500 | ≥1800 | ≥2100 | ≥2400 | ≥2800 | |

| anti acid and alkaline | % | breaking strength remain 90%,breaksing elongation remain 90% | ||||||||||

| Dry sieve size O90 | mm | ≤0.1 | ||||||||||

| vertical permeability coefficient |

cm/s | ≤0.2 | ||||||||||

| peel strength | N/5 cm | ≥80 | ≥100 | |||||||||

PROJECT CASES

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

Apr 25,2024

FAQ

Are you a factory or trading company?

Could you send the sample before order confirmation?

How long is your delivery time?

Can you produce the product according to customers' requirements?

LISTEN & DELIVER TRUSTED SOIUTIONS.

DOWNLOADS